Add to Cart

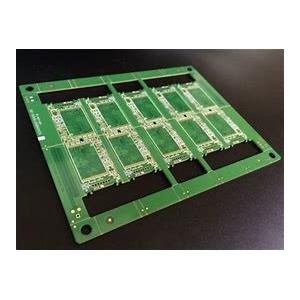

Automation 8 Layer HDI Boards High Precision For Storage Card Boards

HDI PCBs take advantage of the most recent technologies existing to amplify the functionality of circuit boards by means of the similar or little amounts of area. This development in board technology is motivated by the tininess of parts and semiconductor packages that assist superior characteristics in innovative new products like touch screen tabs.

HDI PCBs are described by high-density features comprising of laser micro-vias, high performance thin materials and fine lines. The better density allows extra functions per unit area. These types of multifaceted structures give the required routing resolution for large pin-count chips which are used in mobile devices and other high technology products.

The placement of the parts on the circuit board needs extra precision than conservative board design due to miniature pads and fine pitch of the circuitry on the circuit board. Leadless chips require special soldering methods and additional steps in the assembly and repair process.

1. Product application

Storage card (SSD) High Density Interconnection (HDI) products can be used in electronic computing and storage devices.

- Convert M.2 NGFF PCIe based SSD to work in main board PCIe x4 bus slot.

- Movable M.2 NGFF stand-offs and multiple plated-holes supports 2280, 2260, 2242 and 2230 SSDs.

- M.2 PCIe SSD gets power from motherboard PCIe bus slot 3.3V.

- Supports industrial operating temperature range: -40 - 85 ºC.

- Motherboard Requirement :An empty PCIe 3.0 or PCIe 2.0 x4, x8, or x16 slot, supports PCIe 2.0 and PCIe 3.0 motherboard.

- Custom pcb board hytepro oem/odm circuit board.

specifications:

| Name | 8Layer HDI for Storage Card boards |

| Layer | 8 |

| Quality Grade | IPC 6012 Class 2,IPC 6012 Class 3 |

| Material | DS7402 |

| Min Track/Spacing | 75um/100um |

| Drilling Size | 100um |

| Solder Mask | Green |

| Silkscreen | White |

| Surface Finish | Immersion gold |

| Finished Copper | 1/3OZ |

| Production time | 10-21 working days |

| Lead time | 2-3 days |

1: We have a high-quality, professional, honest and positive core team. Team members have rich experience in SMT, wave soldering, testing tooling and fixtures. The company has clearly established quality, production, engineering, procurement, warehousing and other departments, and strictly implements the ISO9001 system to ensure orderly production and high quality! 2: We pay more attention to customer needs and product requirements, and pay more attention to product quality and continuous improvement. Customer first is our eternal purpose. The team members have extensive experience in the resource integration of component procurement. We are enterprising, we work hard, we continue to learn, continue to improve, absorb the strengths of others, and make our team more perfect.

What can we do for you?

1) We can offer sample .

2) Competitive Price( Factory direct price).

3) On time delivery.

4) Good customers service.

5) Professional Technology.

6) Quality Control through the whole Manufacturing process.

a. Check the material before the production.

b. Have the random inspection during the production.

c. Make the 100% inspection before the shipment.